| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : APBWR

Place of Origin : China

MOQ : 1 SET

Payment Terms : T/T,L/C

Supply Ability : 1000+ /year

Delivery Time : 5-814work days

Packaging Details : Pallets or wooden crates as per customer's requirements.

Model Number : 2300D

Certification : ISO9001

Price : $5000-50000

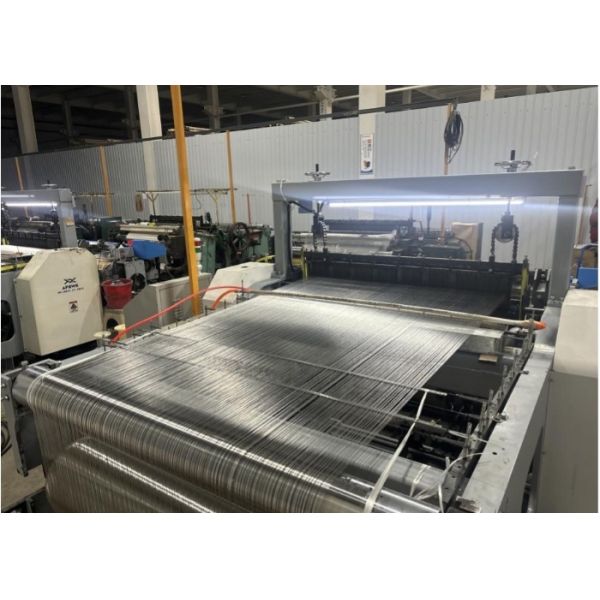

Product Name : Automatic Weaving Mesh Machine Low Maintenance BWR2300D

Keyword : Heavy Duty Wire Mesh Weaving Machine

Weaving Width : Standard: 1000/1300/1600/2000/2300/2500/3000mm (Customizable)

Wire Diameter : 0.1-0.8mm (Stainless steel, iron, aluminum, copper, nickel, polyester, etc.)

Weave Density : Plain weave: 10-100 meshes/inch; Twill weave: Up to 400 meshes/inch

Speed : 80 RPM

Base Tension : 40,000 N/m

Dimensions & Weight : Customized based on width requirement

Automatic Weaving Mesh Machine Low Maintenance BWR2300D

1.Automatic Weaving Mesh Machine Low Maintenance BWR2300D Key Components & Functional Design:

(1) Warper Mechanism (Warp Supply System)

(2) Heddle Lifting Mechanism (Shedding System) - Core Component

(3) Beat-Up Mechanism

Types:

(4) Take-Up Mechanism

(5) Auxiliary Systems

2. Automatic Weaving Mesh Machine Low Maintenance BWR2300D Working Process

3.Automatic Weaving Mesh Machine Low Maintenance BWR2300D Technical Specifications

| Mesh Cutting Folding Machine Parameter Configuration Table | ||

| 1 | Weaving Width | Standard: 1000/1300/1600/2000/2300/2500/3000mm (Customizable) |

| 2 | Wire Diameter | 0.1-0.8mm (Stainless steel, iron, aluminum, copper, nickel, polyester, etc.) |

| 3 | Weave Density | Plain weave: 10-100 meshes/inch; Twill weave: Up to 400 meshes/inch |

| 4 | Speed | 80 RPM (Frequency conversion, speed adapts to weave specifications/width) |

| 5 | Base Tension | 40,000 N/m |

| 6 | Dimensions & Weight | Customized based on width requirement |

4. Core Advantages

| 1 | Continuous Net Winding | Uninterrupted production—cut mesh rolls on-demand without waiting for warp depletion, ideal for flexible order sizes. |

| 2 | CNC Servo Control | Servo motors replace gear drives for simpler structure, lower noise, precise tension control (real-time display & auto-adjustment), and easy maintenance. |

| 3 | Smart Remote Maintenance | Remote diagnostics, parameter adjustment, and repair guidance reduce downtime & operational costs, ensuring 24/7 production reliability. |

| 4 | Modular Design | One machine, multiple products—supports plain, twill, leno weaves and quick pattern switching for diverse mesh types. |

| 5 | Auto-Lubrication & Overload Protection | Automatic oiling for critical parts extends lifespan; overload clutch disconnects drives to prevent damage during stress. |

| 6 | Safety & Quality Assurance | Wire breakage detection + emergency stop system; infrared edge alignment ensures defect-free meshes. |

| 7 | 1-Year Warranty & Customization | Comprehensive after-sales support (spare parts, remote tuning, on-site service) + full customization for width, material, and density. |

5. Applications

Ideal for producing high-strength meshes for:

Why Choose Us?

Contact Us Today for a customized solution that meets your mesh production needs!

|

|

Automatic Weaving Mesh Machine Low Maintenance BWR2300D Images |